side blast forge design

This will allow you to make changes before the final build. Having a burner on top also puts more back pressure on your system which can result in a flame escaping out of the back of your burner.

The 55 Forge Bottom And Side Blast Solid Fuel Forges I Forge Iron

The ends of the 58 rod are put into a hole in each ear.

. A leg is made from 58 square stock with an eye in one end that goes around the 58 rod at the bottom of the U. To the best of my knowledge the bottom blast is a 19th century American innovation designed specifically for coal. I am using used antifreeze as a coolant for two reasons 1 shouldnt rust the Bosh.

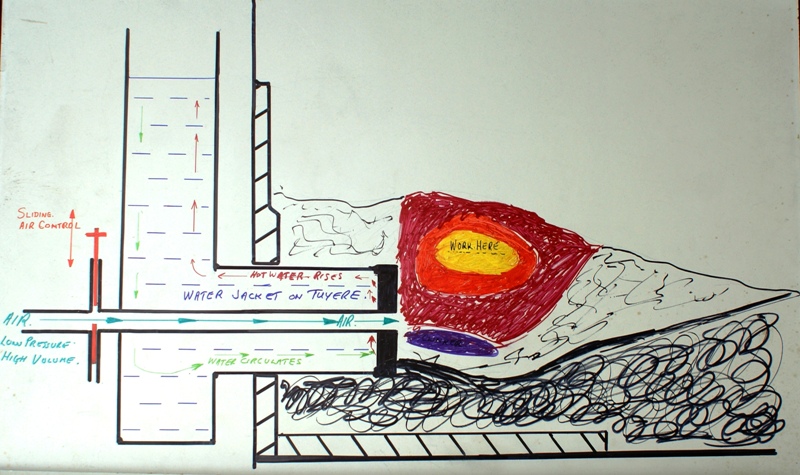

Japforgebmp My first question is. It shows the basic principles of a Water cooled Side Blast Forge. This a Side Blast Forge built in the UK by Mike Judd of Greystone Forge.

Posted March 28 2012. With charcoal it is easier to design a side blast forge. Steel side-draft forge - an example of my latest fabricated small steel sidedraft forge.

The biggest thing to me is insulation and where your forge doors are with a side blast I found that having a door close from the opposite side works best. I use charcoal often and it is real easy to blow the charcoal out of the fire pot with a bottom blast design. Book scans side-blast forges - examples of a style of forge blast that predates our modern firepots.

Side Blast Forge Design. It will work with just a hole in the wall but that will limit somewhat the size of fire you can get hot. 316 Hot rolled plate material was used in the building of this traditionally British Side Blast forge however they have been built out.

The Bosh is connected to the Tuyere with a bottom cold water tube and the top is connected to the hot water tube. Before you set things in concrete pun intended you may want to try a mud fire pot and a 34 inch dia piece of pipe for the side blast forge. A piece of 58 rod is bent into a square-cornered U with 2 inch right angle bends at the top of the U.

First rule of forge design. Below the air blast. Most are from the UK at this time.

Side blast forge design To apply just adhere on the nails we like to maintain them at the base of our nail beds and set with very clear topcoat. Doesnt this design clog up with ash after a while. The idea is that one day when I grow up I will be able to forge swords in it.

My forge has a burner in the side at a 90 degree angle and works fine. When the U is pulled up into place the leg hits the floor and supports it. In the mean time I can use it to get some practice at working some steel.

Here it is in all. An eye-catching style hasnt been less complicated. I have been wanting a side blast forge for a LONG time.

A traditional side blast for charcoal has the tuyere angled slightly downwards coming in about two inches above the floor of a shallow bowl of clay or brick in the bottom of a larger deeper bowl of clay or brick. Now for the testing of the forge. The hearth or ducks nest supports the fire in a position that places the heart of the fire centered half above and half below at the same level as the hearth or side edges of the forge whichever is taller the iron that is to be heated must pass through the center of the heart of the fire when placed on the.

The basic design is as follows. I want to build a side-blast forge very similar to the japanese ones. I have just finished building a Side Blast Forge Mark Aspery design with a Super Sucker Hood and 10 chimney.

Most of the examples on this page show modern use of side-blast tuyeres. The side blast forge can be fabricated by any blacksmith with the tools to cut and weld steel plate and pipe. After doing a lot of research and collecting up materials I have finally built one.